How to judge whether an infrared induction led light is damaged?

Infrared induction led light is widely used in homes, offices, shopping malls, corridors, garages and other places due to its energy-saving, intelligent control and convenient use. They can automatically sense human activities, light up when someone passes by, and automatically turn off when no one is around, thereby effectively reducing energy waste and improving efficiency. During long-term use, infrared induction led light may have some faults, causing it to fail to work properly. So, how to judge whether an infrared induction led light is damaged? Is it still worth repairing? Or does it need to be replaced directly?

This article will analyze in detail the working principle, common fault manifestations, detection methods and maintenance suggestions of infrared induction led light to help users quickly judge whether the infrared induction led light is damaged and take corresponding treatment measures.

What is the working principle of infrared induction led light?

To judge whether the infrared induction led light is damaged, you first need to understand its working principle. The core technology of infrared induction led light mainly relies on infrared sensor and LED lighting technology, and its working process is as follows:

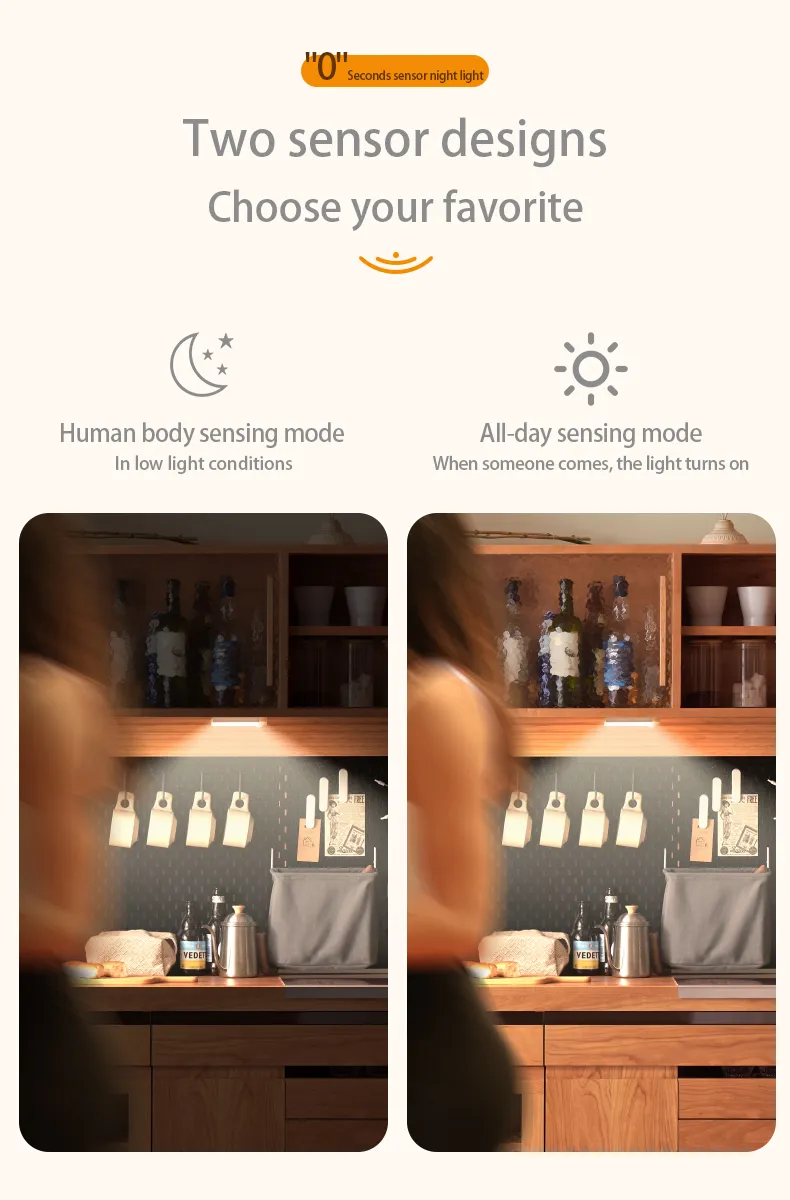

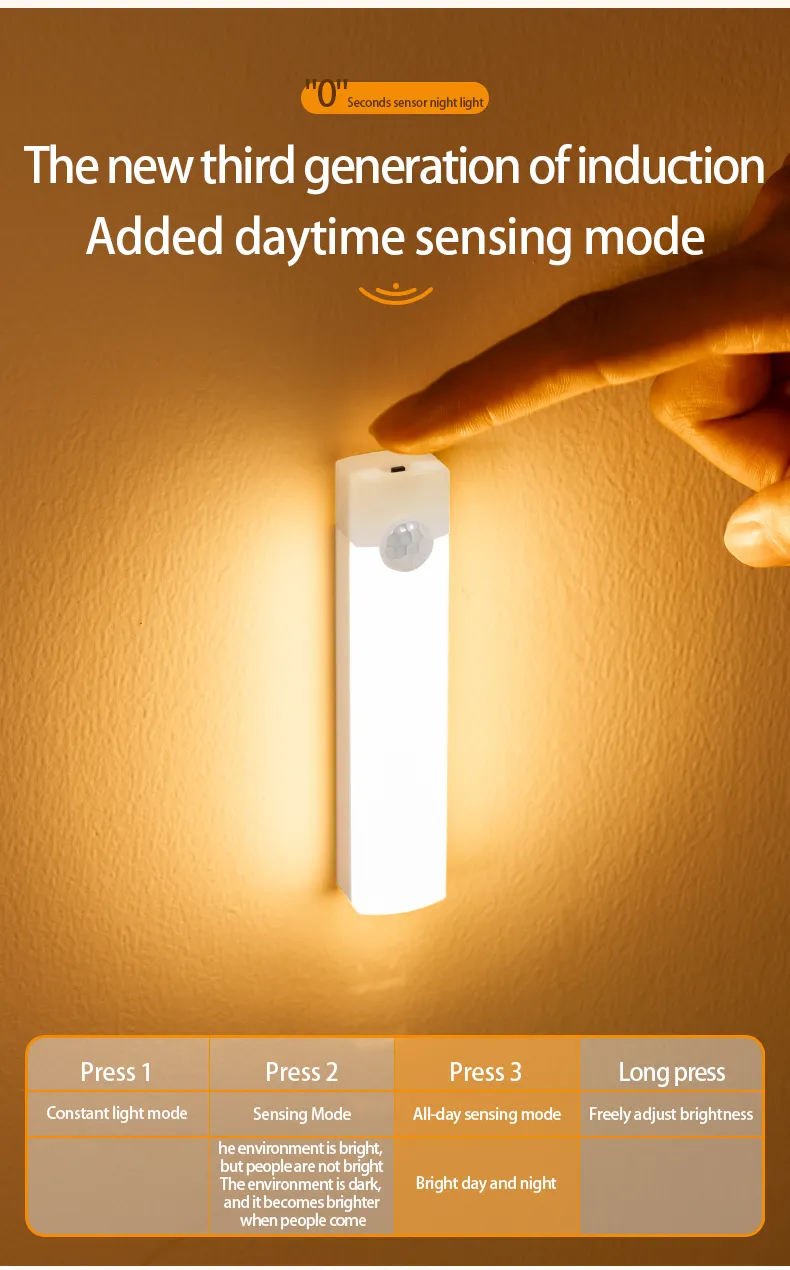

● Human body sensing: The passive infrared sensor (PIR sensor) built into the infrared induction led light can detect infrared rays emitted by the human body. When the human body approaches the lamp, the sensor detects the change of infrared signal and triggers the LED light to light up.

● Automatic shutdown: When the human body leaves the sensing range, the lamp will automatically turn off within the set time.

● Ambient light detection: Some infrared induction led lights are equipped with photosensitive sensors that can detect the brightness of ambient light. If the ambient light is sufficient (such as during the day), the light will not light up even if someone passes by to save energy.

What are the manifestations of infrared induction led light damage?

If the infrared induction led light has the following problems, it may indicate that the lamp is damaged or malfunctioning:

● The lamp does not light up at all: Even in a dark environment and when someone is moving within the sensing range, the light still does not light up.

● Long-term constant light: The infrared induction led light should light up after sensing a human body and turn off when no one is around. But if the lamp remains on for a long time, it may be that the sensing system fails.

● Intermittent on and off: The light flickers on and off, or flickers unsteadily within the sensing range, which may be a circuit failure.

● Abnormal sensing range: The range that could normally sense human activities suddenly becomes smaller, or the sensing angle becomes narrower, which may be due to aging of the infrared sensor or external interference.

● Ambient light sensing failure: When there is sufficient light during the day, the infrared induction led light is still on, indicating that the photosensitive sensor may fail.

How to determine whether the infrared induction led light is damaged?

If your infrared induction led light has the above problems, you can follow the steps below to check whether it is damaged.

1. Observe external damage

First, check whether the appearance of the lamp is obviously damaged, such as cracked shell, burnt LED beads, broken circuits, etc. If the appearance is intact, you can proceed to the next test.

2. Detect power supply problems

Many problems with infrared induction led lights are caused by faulty power connections. You can test it in the following ways:

● Check the power socket or switch: If it is a plug-in infrared induction led light, try to change the socket or use a multimeter to test whether the socket is powered normally.

● Check the wire contact: For LED lights powered by DC (such as battery power), check whether the battery is exhausted or whether the contact is poor.

● Check the power driver: If the LED driver power supply is damaged, the lamp may not light up normally.

3. Test the sensing function

The core component of the infrared induction led light is the infrared sensor, which can be tested in the following ways:

● Night test: In a dark environment, slowly approach the lamp to see if it will be triggered to light up.

● Blocking test: Block the sensor with your hand or an object for a few seconds and then move away to observe whether the lamp responds.

● Change angle test: Move in different directions and distances to see if the lamp can respond sensitively.

4. Test ambient light sensing

If the infrared induction led light is still on during the day, there may be a problem with the light sensor. The test method is as follows:

● Daytime test: Cover the photosensitive sensor (usually located on the surface of the lamp) in a bright environment. If the light is still on, the sensor may be damaged.

● Dark test: Test the sensor light in a completely dark room to see if it can work properly.

5. Check the LED lamp beads and drive circuit

If the lamp can light up briefly, but quickly goes out or flickers, there may be a problem with the LED lamp beads or drive circuit:

● LED lamp beads burn out: If some LED lamp beads do not light up or flicker, the lamp beads may be damaged, causing the lamp to not work properly.

● Drive circuit failure: If the lamp turns off quickly or flickers frequently after lighting, it may be that the drive circuit is aged or damaged.

How to repair or deal with a damaged infrared induction led light?

If it is confirmed that the infrared induction led light is damaged after testing, the following treatment methods can be taken:

● Battery-powered LED lights: Replace the battery and test again. If the problem persists, it may be a poor battery contact or a circuit failure.

● Line or socket problem: Try to change the socket or check whether the power line is damaged.

● Replace LED lamp beads: If only one LED lamp bead is damaged, you can try to replace the damaged lamp bead, but the operation is more complicated and requires professional welding technology.

● Repair the sensor module: If the infrared sensor is faulty, you can try to clean the sensor surface or replace the sensor module.

● Replace the entire lamp: If the lamp is seriously damaged (such as aging of the drive circuit, multiple lamp beads burned out, etc.), it is usually a more economical choice to replace the entire lamp.

Reasonably judge the fault and decide whether to repair or replace

The infrared induction led light is an intelligent lighting device, but various problems may occur after long-term use. Through the methods introduced in this article, users can quickly determine whether the lamp is damaged and take appropriate repair or replacement measures.

The inspection steps are summarized as follows:

● Observe external damage (whether there are cracks or burn marks on the appearance of the lamp).

● Detect power supply problems (check whether the socket, battery, and power driver are normal).

● Test the sensing function (test at different angles and different light environments).

● Check the photosensitive sensor (whether it can correctly identify changes in ambient light).

● Check the LED lamp beads and circuits (whether they are flickering, partially off, etc.).

If the lamp is completely damaged and the repair cost is high after testing, it is recommended to replace it with a new lamp directly to ensure the reliability and safety of home lighting.

Huari Lighting Co., Ltd. has been a leading manufacturer of LED lighting products since 1996. Based in China, our 92,000-square-meter factory produces over 1 million products every month, ranging from LED downlights and ceiling lights to cabinet lights and energy-efficient LED bulbs such as GU10 and PAR. We are ISO 9001 and ISO 14001 certified, ensuring consistent quality control across all stages of production. Our products meet international standards and are CE, RoHS, and ERP certified. Whether you need bulk orders, customized solutions, or promotional pricing, Huari Lighting provides affordable options for businesses worldwide. Contact us now for a quote and learn more about our special offers.