An RGB night light is a night lighting fixture that uses a combination of red, green, and blue primary colors to achieve a variety of color changes. Unlike traditional night lights that emit only a single warm or cool light, RGB night lights can produce a rich variety of color effects.

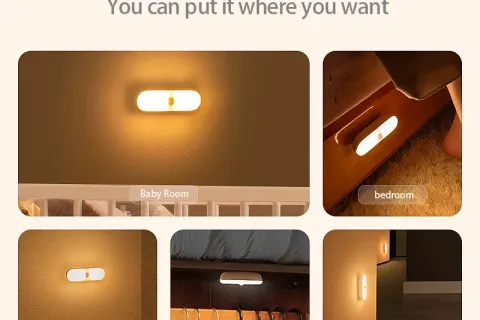

Under-cabinet lighting often has multiple requirements: it must provide sufficient light to effectively illuminate kitchen counters and workspaces while also being simple, energy-efficient, and convenient. For many modern families, the design and functionality of motion sensor LED night lights perfectly meet these needs.

Generally, the lithium batteries used in smart motion sensor lights have a capacity of 600mAh to 2000mAh. Typically, a full charge takes approximately 2 to 4 hours using a standard charger. This provides fast charging and a long battery life.

—The professionally recommended answer is: approximately 60W. This wattage does not directly refer to the LED power, but rather to the luminous flux equivalent of a traditional 60W incandescent bulb, or approximately 800 lumens. This means that only approximately 8W–12W of LED power is needed to achieve the same luminous flux as a traditional 60W incandescent lamp.

Practical research has found that nighttime light should not exceed 10 lux. Warm light with a color temperature between 2700K and 3500K can better simulate natural nighttime light, promote melatonin secretion, and thus help young children fall asleep more quickly. This is why LED night lights are becoming the preferred choice for home use

• Optimal color temperature range: 3000K–5000K • Low-end 3000K: Warm and soft, suitable for evening skincare or creating a cozy atmosphere • Neutral 4000K: Close to natural light, suitable for daily makeup application • High-end 5000K: Bright and clear, suitable for shaving or quick makeup application

Compared to traditional incandescent and CFL bulbs, LED bulbs offer significant performance and effectiveness advantages, which is why they are widely recommended for bathroom vanity bulbs. LED vanity wall lights, in particular, offer the following advantages: 1. Uniform, natural light 2. High brightness at low power consumption 3. Long lifespan and minimal maintenance 4. High safety 5. A wide range of color temperatures

In professional terms, these products are often referred to as "color-changing LED night lights" or "RGB LED night lights," where RGB stands for the three primary colors of red, green, and blue. By combining different red, green, and blue light sources, nearly any visible color can be generated, thus achieving color-changing functionality.

Most motion sensor night lights currently on the market use an integrated LED design. Integrated LED lamps integrate an LED light source with a circuit module, heat sink, and sensor. Unlike traditional light bulbs, integrated LED light sources are not removable or replaceable components.

LEDs (Light Emitting Diodes) are solid-state light sources that generate light using semiconductor materials. Compared to traditional incandescent and fluorescent lamps, LEDs offer several distinct advantages, making them particularly suitable for use in dressing table lighting.

Motion-activated LED lights rely on accurate sensor detection to operate. If the sensor misoperates, the light may turn off without apparent cause. Common causes of malfunction include: • Improper sensor placement • Environmental interference • Small sensing area

• For a single person: One or two vanity wall lights are sufficient. • For two people using the bathroom simultaneously: We recommend at least three vanity wall lights, typically on both sides and one above, to ensure adequate facial illumination for each user.